Dam safety is critical to protecting downstream communities, infrastructure, and the environment. Monitoring dam deformation is key to maintaining their structural integrity, helping to identify potential problems before they lead to major failures. Historically, monitoring has often relied on optical total stations. While effective, these stations have a number of shortcomings.

Recent advances in Global Navigation Satellite System (GNSS) technology, such as the CHCNAV H3 GNSS receiver, are transforming the dam structural health monitoring approach. This technology provides continuous, highly accurate measurements that give us a detailed picture of a dam's structural health, overcoming the limitations of traditional methods.

Figure 1. CHCNAV H3 receiver installed on dam and landslide-prone area for deformation monitoring.

THE ESSENTIAL NEED FOR PRECISE DAM DEFORMATION MONITORING

Uncovering the Forces Behind Dam Deformation

Dams face a number of natural and man-made forces that can weaken their structure over time. Water pressure, environmental changes, and seismic activity are key factors that can cause significant structural changes. Even small deformations can signal severe structural problems that threaten the dam's stability and, as a result, the safety of communities and ecosystems downstream. Early detection and response to these small displacements is critical and underscores the need for continuous and accurate deformation monitoring.

Aging Infrastructure: A Growing Concern

The issue is becoming more pressing as the world's dam infrastructure ages. Many existing dams, designed and built decades ago, operate beyond their original life expectancy. As materials age and deteriorate under the constant pressure of environmental forces, these structures become more susceptible to failure.

Principles of Dam Deformation Monitoring

At its core, dam deformation monitoring requires careful measurement of changes within the dam structure using stable reference points for comparison. These measurements allow engineers to identify shifts over time, providing valuable insight into the structural health and stability of the dam. Effective monitoring depends on the accuracy and reliability of these measurements and requires advanced technologies that can detect even the smallest movements and convert them into valuable data.

TRANSITIONING FROM TRADITIONAL TO ADVANCED MONITORING TECHNIQUES

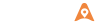

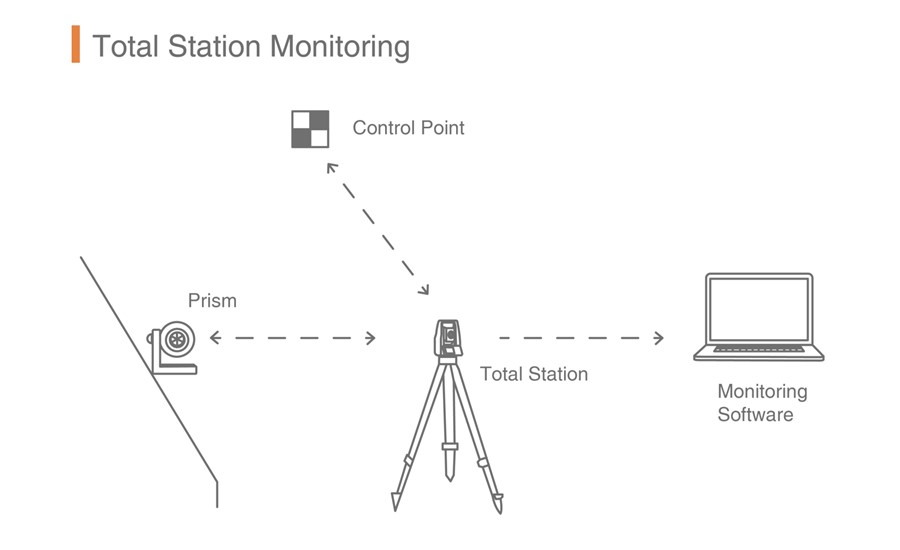

Figure 2. The schematic representation of the dam monitoring with a total station.

The Limitations of Conventional Total Station Systems

Despite their widespread use and reliability for precise measurements, total station systems present several challenges in dam deformation monitoring. These challenges include:

- Line-of-Sight Dependency: Total stations require a clear line of sight between the instrument and target points, which is often difficult to achieve in complex terrain and structures around dams.

- Measurement Intervals: The need for manual operation limits data collection to discrete intervals. This intermittent data collection can miss critical movements and fail to capture the full extent of deformation trends.

- Environmental Sensitivity: As optical instruments, total stations are susceptible to weather conditions that can disrupt measurements and reduce data accuracy in adverse weather conditions.

These limitations require a more robust and continuous monitoring solution, especially for critical infrastructure such as dams where safety and operational integrity are paramount.

LEVERAGING THE POWER OF GNSS TECHNOLOGY FOR SUPERIOR DAM MONITORING

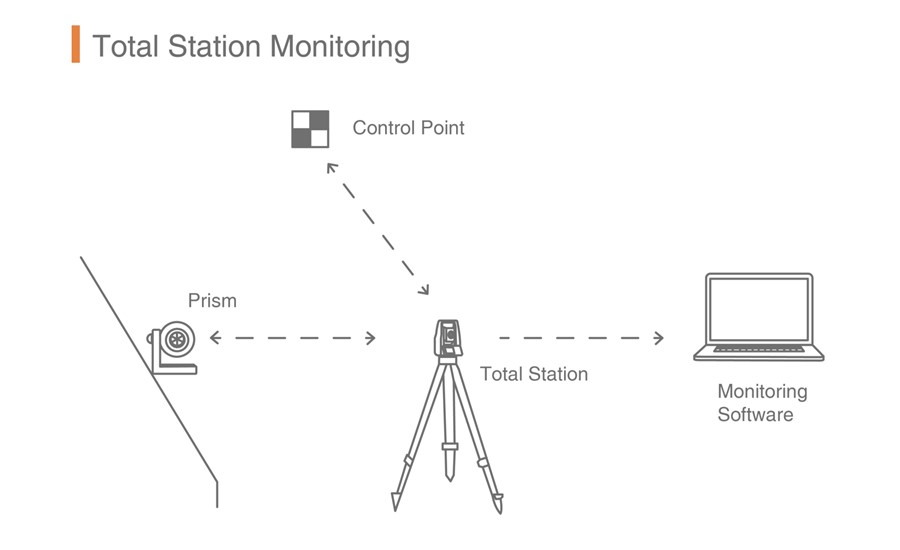

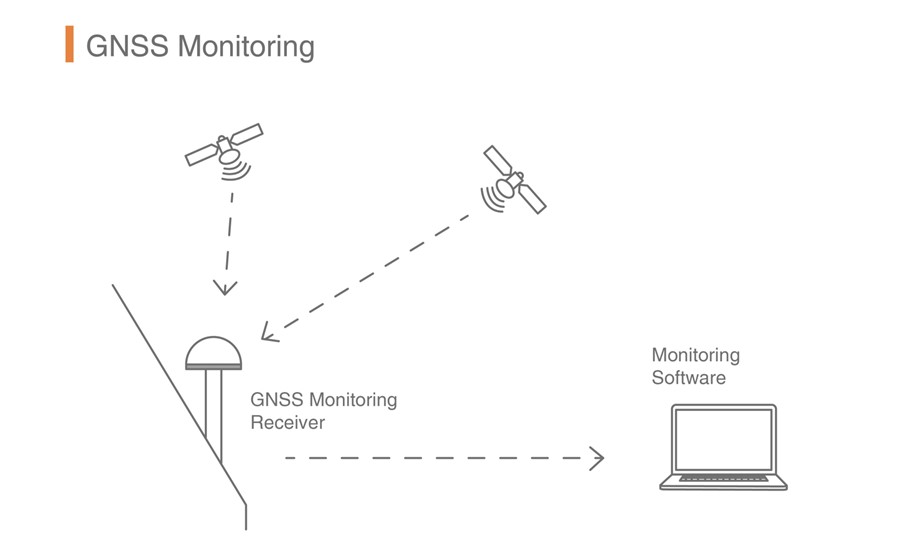

Figure 3. The schematic representation of the dam monitoring with GNSS receiver.

The field of dam safety management is undergoing a significant change with the introduction of Global Navigation Satellite System (GNSS) technology. GNSS systems, particularly the CHCNAV H3 GNSS receiver, offer several unique advantages for deformation monitoring and are leading this transformative change. This technology not only provides continuous, high-precision measurements but also brings new levels of automation and flexibility that go beyond what was possible with traditional monitoring approaches.

Continuous, High-Precision Measurements

A major advantage of GNSS technology is its capability to provide continuous, automated monitoring without the need for direct line-of-sight or manual input. This is incredibly valuable for dam deformation monitoring, where constant environmental and structural changes require uninterrupted attention. A network of GNSS receivers is strategically placed across the dam structure, providing extensive coverage and the ability to detect very small movements with sub-millimeter accuracy.

Advanced Algorithms and Error Correction

The accuracy of GNSS monitoring is greatly enhanced by advanced algorithms and error correction methods. Technologies such as Precise Point Positioning (PPP) and Real-Time Kinematic (RTK) enable the CHCNAV H3 to achieve millimeter-level accuracy. This high level of accuracy is critical for the early detection of potential structural problems, enabling timely action and reducing the risk of potentially catastrophic failure.

Uncompromised Performance in Adverse Conditions

A key feature of GNSS technology is its strong performance in a variety of environmental conditions. Unlike traditional optical measurement methods, GNSS signals remain reliable even in challenging weather conditions such as fog, rain, and snow. This resilience ensures that dam deformation monitoring can continue uninterrupted regardless of weather conditions, providing a continuous stream of data essential for long-term dam safety and performance evaluation.

Remote Monitoring and Scalability

The possibility of remote operation is a significant advancement in monitoring technology. GNSS systems allow remote operation and data collection, reducing the need for on-site personnel and enabling real-time data analysis from virtually anywhere. This feature is particularly beneficial for monitoring dams in remote or hard-to-reach areas. In addition, the scalable design of GNSS monitoring networks allows for easy expansion to cover larger areas or support more comprehensive measurement campaigns, providing a flexible and adaptable approach to meeting changing monitoring needs.

Addressing the Challenges

While GNSS technology offers many advantages over traditional total station methods, it also introduces new factors to consider, such as the need for each monitoring point to have its own GNSS receiver and the necessary power and communications infrastructure. However, the advantages of GNSS technology—particularly its accuracy, reliability, and adaptability—outweigh these logistical hurdles.

Figure 4. The H3 mounted on the dam meets rigorous monitoring needs.

Introducing the CHCNAV H3 GNSS Receiver: Innovating Dam Deformation Monitoring

At the forefront of GNSS technology for structural deformation monitoring, the CHCNAV H3 GNSS receiver stands out as a sensor specifically designed to meet the rigorous demands of dam monitoring. This compact, all-in-one device combines high-precision GNSS functionality with state-of-the-art data processing and connectivity features to provide outstanding accuracy, reliability, and ease of use in demanding conditions.

Superior Precision and Reliability

The CHCNAV H3 features a high-accuracy GNSS module and supports a variety of satellite constellations, including GPS, GLONASS, BeiDou, Galileo, and QZSS. This broad constellation support ensures extensive GNSS signal availability and consistent accuracy, reducing data collection gaps and improving deformation measurement reliability.

Enhanced Monitoring with Integrated MEMS Sensor

A notable feature of the H3 GNSS receiver is its integrated MEMS sensor, which adds tilt and acceleration data to enhance GNSS-based measurements. This additional layer of data improves the integrity and reliability of the monitoring system by detecting and compensating for any movement or instability of the receiver, ensuring that measurements accurately reflect structural changes rather than equipment-related issues.

Seamless Connectivity for Real-Time Insights

Connectivity is central to the design of the H3, which incorporates various communication modules such as a 4G modem and Ethernet. These features enable real-time data transmission and remote access, ensuring a continuous flow of information for timely decision-making and action. The ability to remotely configure and manage receivers increases the system's adaptability and responsiveness to changing conditions and needs.

Built to Endure: Rugged Design for Harsh Environments

Designed with the challenging and often remote settings of dams in mind, the CHCNAV H3 is built for durability. Its IP67-rated casing offers dust and water resistance, and its low power consumption (less than 2W) supports extended field operation. This mix of robustness and efficiency makes the H3 ideally suited for long-term use in demanding environments, delivering steady performance with minimal upkeep.

Ease of Installation and Integration

The H3's compact, integrated design simplifies the setup process and eliminates the need for complex on-site installations and additional equipment. Compatibility with industry-standard software ensures that the H3 can be easily integrated into existing dam monitoring systems, providing a smooth transition to GNSS technology.

LOOKING AHEAD: A FUTURE ANCHORED IN GNSS TECHNOLOGY

Incorporating GNSS technology into dam deformation monitoring practices marks a transition to a new era in managing these critical assets. By leveraging GNSS technology, dam operators and engineers can improve these sensitive structures' safety, reliability, and longevity. Looking to the future, continued advancements in GNSS solutions, such as the CHCNAV H3, will further enhance our ability to monitor and maintain the structural integrity of dams, protecting the communities and ecosystems that depend on them.

____

About CHC Navigation

CHC Navigation (CHCNAV) creates innovative mapping, navigation, and positioning solutions to make customers' work more efficient. CHCNAV products and solutions cover multiple industries such as geospatial, construction, agriculture, and marine. With a presence across the globe, distributors in more than 120 countries, and more than 1,700 employees, today, CHC Navigation is recognized as one of the fastest-growing companies in geomatics technologies.