CHCNAV is a global provider of geospatial technologies to optimize mining operations.

CHC Navigation (CHCNAV) creates innovative navigation and positioning solutions to make customers' work more efficient. CHCNAV products and solutions cover multiple industries such as geospatial, machine control, construction, agriculture, and marine. With a presence across the globe, distributors in more than 120 countries, and more than 1,500 employees, CHC Navigation is recognized as one of the fastest-growing companies in geomatics technologies.

Nowadays, mining companies are often under extreme pressure to reduce costs, increase efficiency and improve safety performance while maintaining high production quality. There are no easy solutions, but it is clear that technology is making a significant contribution to mining operations. Digitizing mining and quarrying sites with CHCNAV's systems helps optimize production processes. The use of appropriate and reasonably priced surveying technology, combined with adequate professional training of personnel, makes the operation of mining companies more efficient, strengthening the overall production process and thus increasing revenues.

Although the mining industry differs from country to country, the implementation of new technologies in the mining sector frequently results in a series of difficulties. Below, we explore 3 common challenges the mining industry currently faces in the widespread adoption of advanced technologies in 3D mapping, GNSS surveying, and machine control.

1. High-tech solutions, such as laser scanners, unmanned aerial systems (UASs), advanced positioning systems, rugged field data controllers and tablets, surveying and mapping, and data processing software, are often associated with high costs and may therefore be considered out of reach from a financial point of view. In addition, mining companies may have difficulties recruiting highly qualified employees as they prefer to use up-to-date equipment such as GNSS receivers, photogrammetric drones, and Lidar

2. Harsh operating environments and remote, hard-to-reach locations of sites have an effect on machinery and equipment that must withstand the tough conditions of the reality in which they operate. Mining companies need durable, rugged equipment with strong dust and water protection that can survive a wide range of operating temperatures.

3. Existing outdated survey tools may be technologically difficult to replace in a short period of time without influencing operation processes. Moreover, veteran employees may be reluctant to learn to use new equipment and different software, such as in the case of switching from theodolites to GNSS technology.

WHAT PRACTICAL SOLUTIONS DOES CHCNAV PROVIDE GLOBALLY TO MINE SITE MANAGERS?

1. CHC Navigation delivers affordable, up-to-date, and high-quality technologies that meet the specific needs of mines and quarries.

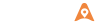

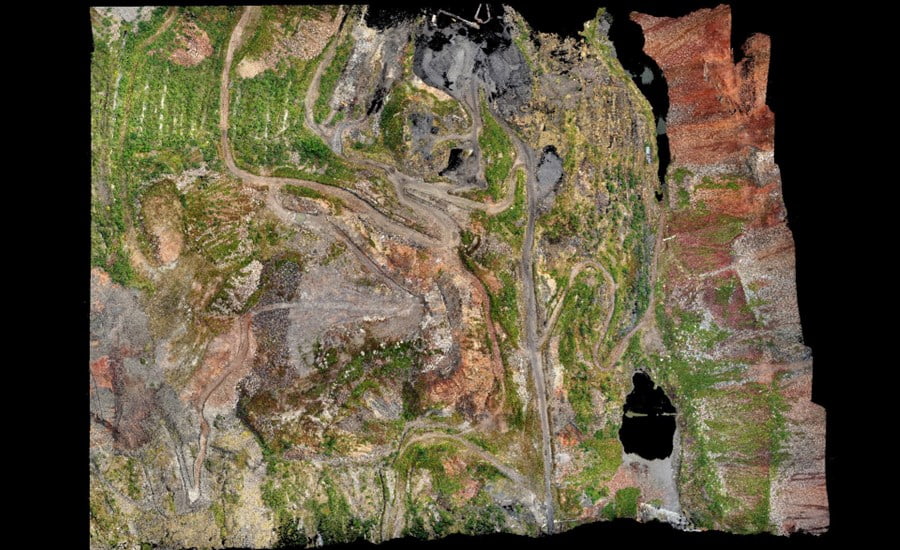

Efficient 3D Mappers and Scanners - Collecting, processing, and maintaining high-density 3D geospatial data of mines with mobile mapping solutions, like UAVs (drones) and 3D LiDAR scanners, is highly cost-effective. Light Laser Detection and Ranging (LiDAR) is one of the most cutting-edge technologies in the field of surveying and mapping today. Installed on a drone for mining surveys, it measures the three-dimensional coordinates of the terrain as dense point clouds to generate a high-precision digital terrain model (DTM). Aerial surveying eliminates safety concerns for on-site surveyors, and it takes only minutes to hours to complete the measurement of the entire site, significantly improving production efficiency.

Figure 1. Mining site point cloud with the RGB colorization made in CoPre Software from AA450 LiDAR scanner and BB4 UAV data.

Robust and Reliable Land Surveying Instruments - Surveying in the mining industry serves a critical function in providing essential information to all the other mining disciplines. From site development to topographic surveys, the GNSS Smart Antennas or Receivers, rugged Field Data Controllers And Tablets, and Surveying and Mapping software are all bringing accuracy and efficiency to mining sites. The optimized workflow and extreme reliability of CHCNAV survey and mapping solutions ensure projects' timely completion while offering exceptional revenue value.

Figure 2. Setting up control points with CHCNAV GNSS receivers around a quarrying site in Indonesia.

Affordable and Rugged Machine Control Solutions - CHCNAV GNSS RTK sensors are specifically designed for reliable positioning, automation and guidance of mid-large haul trucks, drilling machines, mining conveyors, excavators, dozers, and other machines. Machine control systems for mining vehicles help operators save time and fuel. They improve operator productivity and safety while enhancing overall equipment reliability, making open pit mining more cost-effective and efficient.

Figure 3. Mining truck in China equipped with the CGI-610 high-precision GNSS+INS sensor.

Mining companies commonly employ motor graders to construct and maintain haul roads with flat and smooth surfaces. The CHCNAV's latest automatic 3D grade control system, the TG63, improves the quality and efficiency of grading operations. The system combines dual-GNSS satellite positioning with inertial navigation to ensure the ultimate accuracy, regardless of the machine's position. As a result, overall efficiency and productivity are increased significantly with the TG63, eliminating the need for manual staking while safety is always guaranteed for everyone involved.

Figure 4: The TG63 automatic GNSS/INS system for motor graders.

Easy to deploy GNSS RTK Site Positioning - All preparatory, maintenance and on-demand topographic surveys in remote areas can be performed timely and accurately with a single GNSS RTK reference station connected to a GNSS choke-ring antenna to provide reliable, uninterrupted RTK services to field crews, drilling operations, and heavy loaders, or by implementing a local GNSS RTK network to cover larger sites.

GNSS Continuously Operating Reference Stations (CORS) provide real-time navigation services but also a solution for mine subsidence monitoring and hazard early warning systems. Subsidence-related accidents are a major concern for the safety of mining sites. The implementation of GNSS monitoring techniques proves to be a crucial element, especially in mining sites located in areas with a high risk of geological disasters.

Figure 5. CHCNAV’s GNSS reference station installed with a choke-ring antenna in Laos

GNSS RTK receivers and sensors, field controllers and tablets, machine control systems, GNSS RTK networks, Unmanned Aerial Vehicles (UAVs or ‘drones’), and LiDAR scanners are all the solutions CHCNAV provides to help to mine and engineering companies increase their productivity.

2. The IP67 (water and dust protection) certification level, multiple power sources, and the ruggedness of the CHCNAV products provide maximum confidence in their daily use and drastically reduce hardware downtime.

The mining solutions from CHCNAV are ready to meet the requirements of the most demanding application. For example, the CGI-610 GNSS/INS system has IP67 dust and water-resistant certification and industrial-grade power management integrated circuit guarantees reliable and consistent operation in the harshest environments. It is also vibration and shock resistant and is protected against electrostatic discharge.

Another example is the P5 GNSS geodetic reference station, which supports dual external power inputs to ensure a stable and continuous electrical supply. The built-in high-capacity 17,000 mAh battery provides up to 20 hours of non-stop backup operation in the event of an external power outage. Its advanced power supply ensures uninterrupted operation 24 hours a day, 7 days a week, with continuous status information on its control screen and the option of remote monitoring of power supply conditions, network status, firmware version, etc. It is also IP67-rated water and dust resistant to withstand challenging conditions at installation sites, reducing potential downtime due to moisture or dust ingress.

3. With CHC Navigation, obsolete surveying systems can be replaced easily and seamlessly without affecting production processes. The adoption of GNSS technologies for new users will lead to the simplification of work processes, and systematic training sessions with field operators will result in increased productivity and a rapid return on investment.

The integration of GNSS+Inertial technologies into GNSS smart antennas allows field crews to survey points without the need to perfectly level the survey range pole, making the surveying task even more reliable and easy. Software development also plays an important role in new technology uptake by enabling workflow automation: safety checklists for drones, codification of topographic surveys for optimal data processing with third-party CAD software, and more.

CHC Navigation provides essential support services, including online technical assistance, powerful proactive support resources, and product updates. Various professional training courses are available for all our GNSS products and integrated solutions, from the GNSS Survey introduction for beginners to the 3D Mobile Mapping data acquisition and processing for advanced users. CHCNAV provides regular and on-demand training sessions at its headquarters or Regional Offices, as well as on-site through our network of certified partners.

___

About CHCNAV

CHC Navigation (CHCNAV) creates innovative GNSS navigation and positioning solutions to make customers' work more efficient. CHCNAV products and solutions cover multiple industries such as geospatial, construction, agriculture, and marine. With a presence across the globe, distributors in more than 120 countries and more than 1,500 employees, today CHC Navigation is recognized as one of the fastest-growing companies in geomatics technologies.