Capturing reliable and accurate survey data for dynamic monitoring objectives has long been a challenge for the mining industry. Recognizing the importance of providing essential insights to mine management, engineering, exploration, and operations specialists, we have embarked on a mission to address this challenge and deliver efficient solutions for making informed operational decisions and achieving high-efficiency gains.

In today's landscape, UAV LiDAR technology is emerging as a critical tool for mineral resource exploration, evaluation, mine development, and exploitation. This advanced technology offers several advantages over traditional surveying techniques, including faster data collection and processing, increased accuracy, enhanced operational safety, and ultimately a stronger foundation for management decisions and improved ROI.

MEETING THE CHALLENGE OF EFFECTIVE DYNAMIC SUPERVISION IN A OPEN-PIT MINE

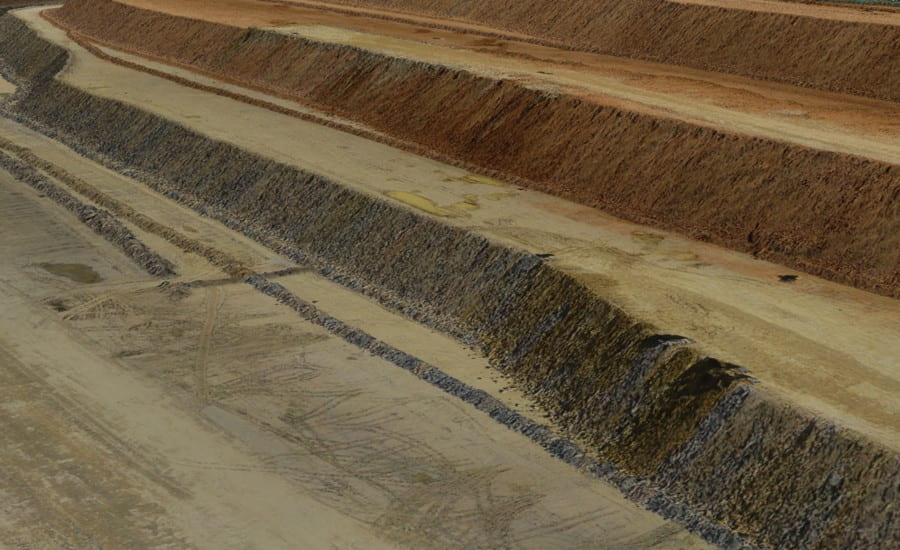

In this case study, we address the challenges of a dynamic mineral resource monitoring project in Mongolia. The goal was to produce highly accurate point cloud data, Digital Orthophoto Maps (DOM), and Digital Elevation Models (DEM) for an extensive open pit mine covering an area of 3 km2 with a depth of 200 meters.

With a continuous stream of heavy machinery and constant traffic at the mine site, time was of the essence. Regular updates of terrain data were critical due to the use of an auxiliary driving system. The project required meeting strict timelines for dynamic monitoring and delivering highly accurate data, which presented a significant challenge.

Internal and external operators have traditionally used total stations, terrestrial laser scanners, and GNSS RTK antennas. However, these methods would take approximately one week to complete the survey. This timeframe did not meet the requirements, and a more efficient solution was needed to provide accurate data.

OVERCOMING THE DIFFICULTIES OF SURVEYING MINES WITH AIRBORNE TECHNOLOGY

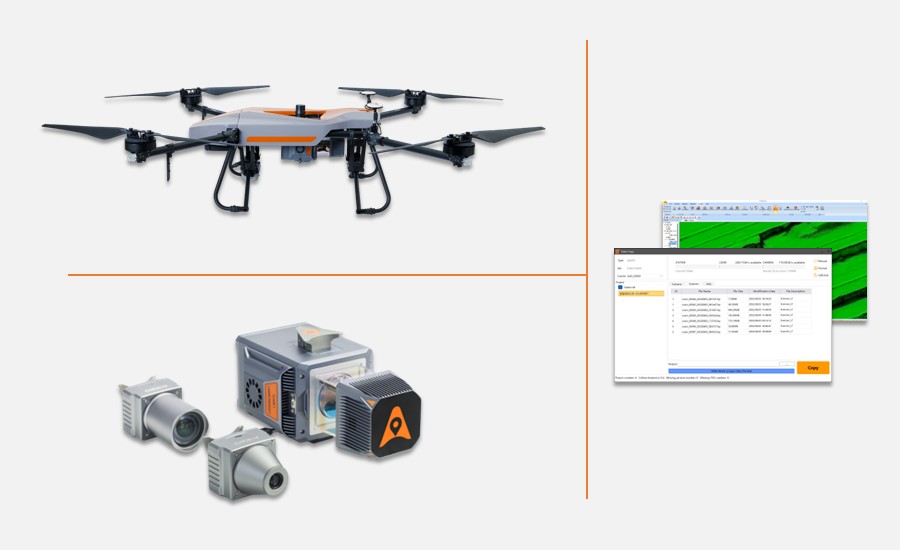

To achieve the project goals, we leveraged the latest technology using a combination of the BB4 UAV, AlphaUni 20 LiDAR system, and CoPre & CoProcess software.

The AlphaUni 20 (AU20) represents a new era in premium, cost-effective, multi-platform mobile mapping systems. Its exceptional capabilities deliver superior data and increase survey efficiency through the extended range, high accuracy, and data density. The AU20 provides accurate point cloud and high-resolution imagery for a wide range of applications.

Figure 1. BB4 UAV, AlphaUni 20 LiDAR system and software from CHCNAV.

In this application, the AlphaUni 20 LiDAR system is combined with advanced data processing software, CoPre, to enable seamless joint modeling of point clouds and images. In addition, CoProcess software plays an essential role in the automatic and efficient extraction of upper and lower slope lines. By comparing multi-period data, it enables high-precision automatic calculation of the volume quantity, providing results on the same day as data acquisition.

The overall process and timeline of the operation was as follows:

1) Preparation: a few minutes to install the AU20 on the BB4 UAV.

Figure 2. AlphaUni20 installed on BB4 UAV for the open pit mine survey in Mongolia.

2) Field data collection: 90 minutes for two airborne missions.

The AlphaUni 20's long-range scanning capabilities are impressive, reaching up to 1450 m with a wide 360° field of view (FOV). Its high-speed measurement capabilities of 2M points per second are made possible by a 200 Hz continuously rotating mirror. This technology ensures the delivery of enhanced detail for all critical surveying tasks.

Complementing the AU20 with the BB4 UAV, explicitly designed for professional applications. With automatic take-off and landing capabilities, the BB4 UAV streamlines operations and ensures ease of use. Its modular design with pre-installed arms and antennas significantly reduces setup time, allowing the platform to be operational in as little as 2 minutes.

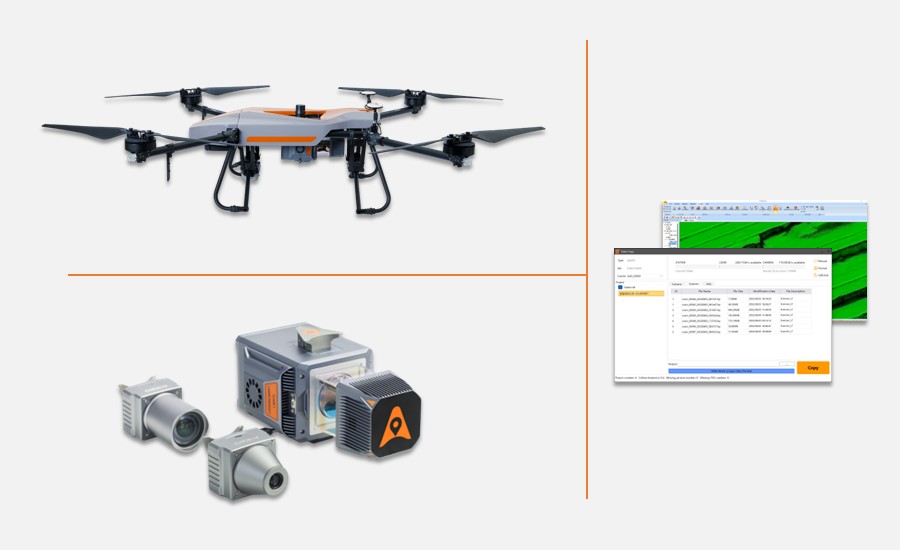

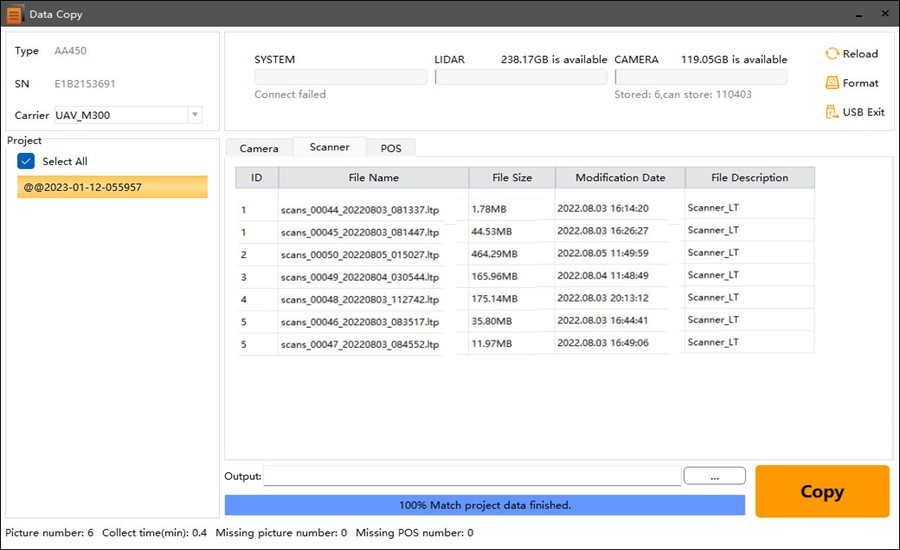

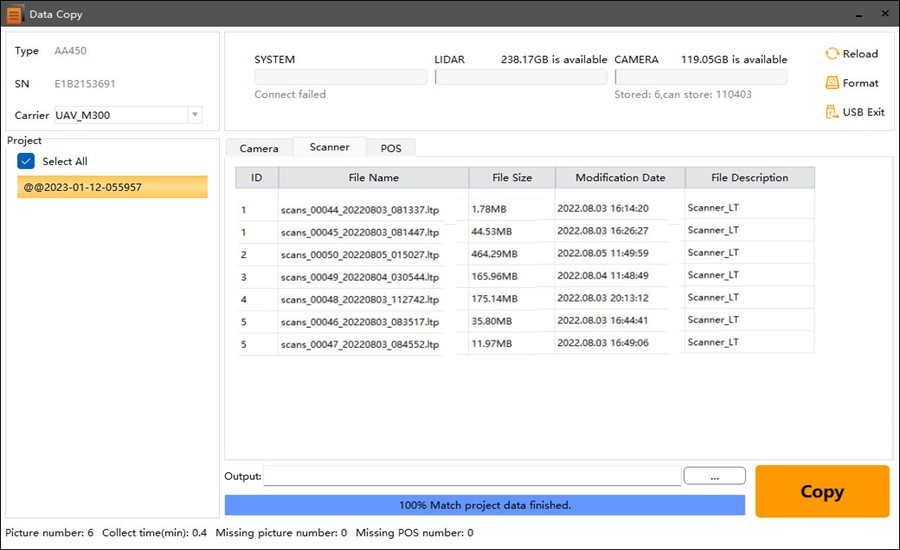

3) Data Processing: 160 minutes for information handling.

Figure 3. Data Processing in the CoPre Software.

After data collection, the AU20's memory card was retrieved, and the CoPre software automatically and seamlessly copied the information. The software efficiently generated point cloud data and digital orthophoto maps (DOM), completing the process in approximately 130 minutes.

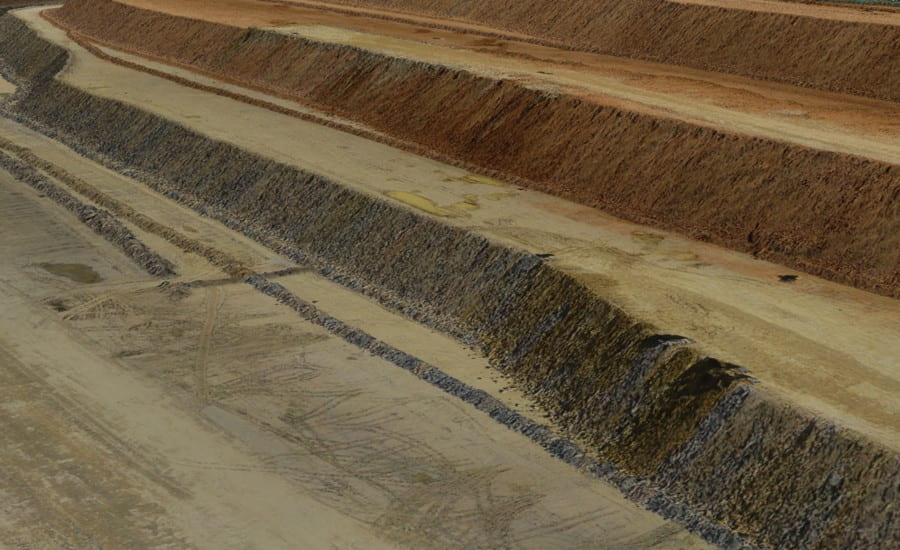

Figure 4. The point cloud data results of the surveying site's area.

Figure 5. Digital Orthophoto Maps of the surveying site's area.

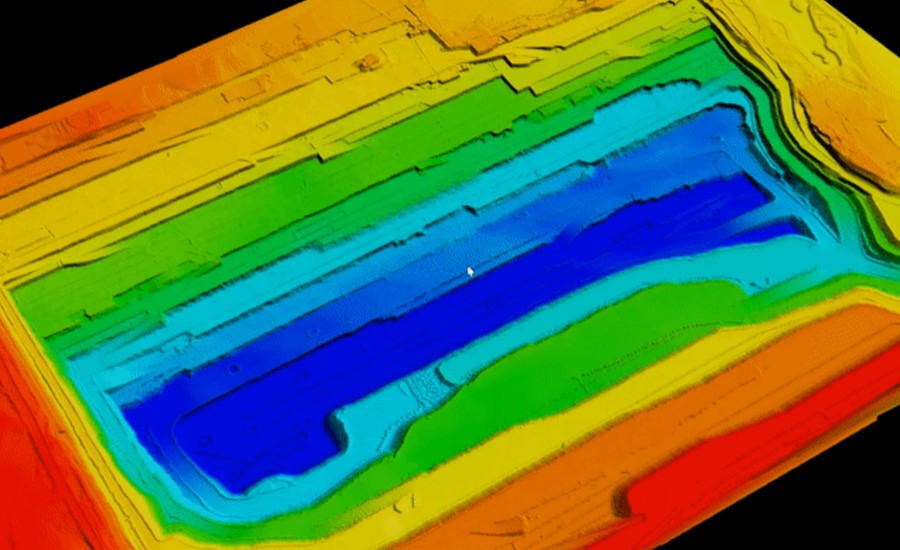

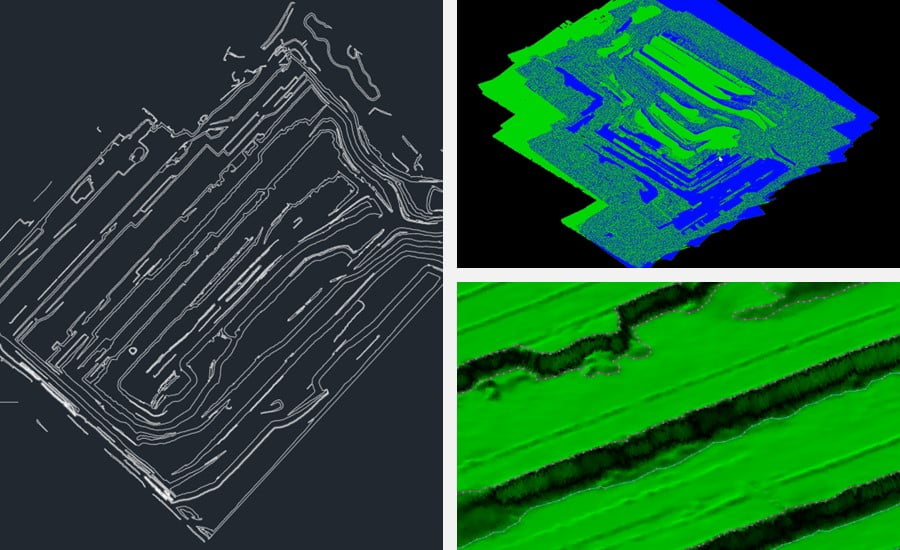

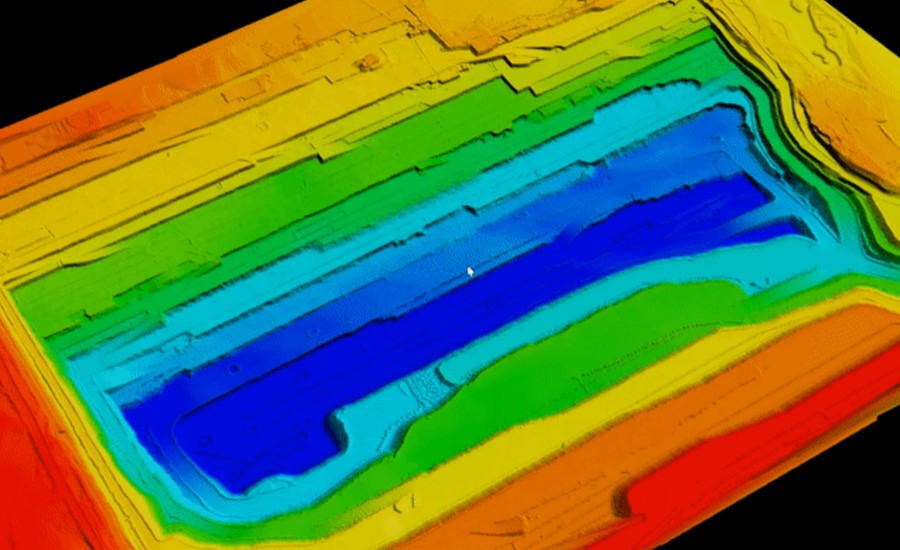

The next step involved denoising and filtering the point cloud using CoProcess software, which quickly generated a highly accurate Digital Elevation Model (DEM) with a single click. Remarkably, the 8 GB point cloud data was processed in just 20 minutes.

Figure 6. Digital Elevation Model of the surveying site.

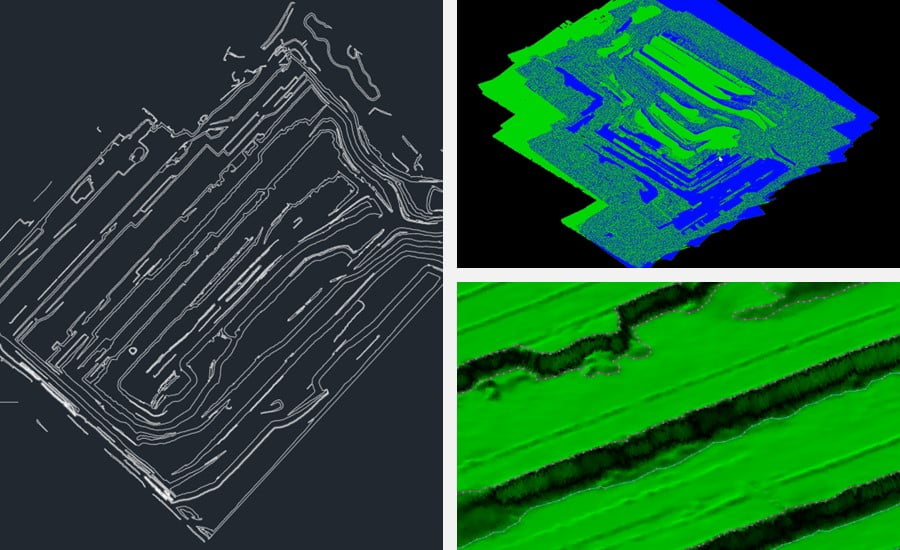

A fusion model (FUM) was generated, integrating both Digital Orthophoto Map (DOM) and Digital Elevation Model (DEM) data. This fusion model allowed the top and bottom lines of the slopes to be identified with precision and accuracy.

Figure 7. Fusion model of DOM and DEM for the surveying site’s area.

Figure 8. From left to right: slope lines checkup in CAD; different periods of data analysis, and slope lines data generation in CoProcess.

By using the point cloud data collected at different intervals, the fill/excavation and total volume calculations were efficiently completed in only 10 minutes.

The capabilities of the AU20 enabled the seamless acquisition of ground surfaces and the generation of accurate Digital Elevation Models (DEMs) and Digital Surface Models (DSMs), even in the most challenging environments.

BENEFITTING FROM HIGH-QUALITY DATA AND A BETTER BASIS FOR DECISION-MAKING

This project in Mongolia was completed in just 2 flight missions, taking a total of 90 minutes to complete data collection for the entire 3 km² site. The operation involved a two-person team handling the office work. One team member was responsible for data pre-processing in CoPre, which took approximately 130 minutes to generate point cloud data and DOM. Meanwhile, the other team member used CoProcess for data post-processing, DEM generation, upper and lower slope line identification, volume quantity calculation, and other related tasks, all completed in 30 minutes.

By using the AU20 long-range LiDAR system, this project achieved an outstanding 5x improvement in overall mine survey efficiency compared to traditional surveying methods.

With a frequency of 2 million points per second, the AU20 effectively reproduces the surface shape of the mine, while its repeatability of 5mm guarantees the accuracy required to produce a 1:500 topographic map. The implemented solution provides a number of invaluable operational outputs, including:

- topographic maps for operational purposes;

- high-precision data to enable automatic driving of mine vehicles;

- strong technical support for dynamic supervision;

- increased efficiency and decision-making reliability, reducing safety risks to personnel and equipment.

Innovative surveying and mapping solutions, such as the CHC Navigation's AU20, provide unparalleled opportunities for companies and government organizations to significantly improve project performance in terms of time, cost, and quality.

CHC Navigation and its local partners are available to discuss your operational challenges. We welcome your questions and look forward to exploring how our expertise can benefit your organization.

___

About CHCNAV

CHC Navigation (CHCNAV) creates innovative mapping, navigation, and positioning solutions to make customers' work more efficient. CHCNAV products and solutions cover multiple industries such as geospatial, construction, agriculture, and marine. With a presence across the globe, distributors in more than 120 countries, and more than 1,700 employees, today, CHC Navigation is recognized as one of the fastest-growing companies in geomatics technologies.